Why Crack Sealing Matters in Oklahoma City

Oklahoma City’s weather can be tough on asphalt. Hot summers, cold winters, and heavy rain create perfect conditions for cracks to form. Over time, those small cracks let water slip below the surface, softening the base and causing the pavement to break apart.

That’s why crack sealing is one of the most important steps in any asphalt maintenance plan. It helps stop small problems before they grow into expensive repairs. Two of the most effective methods are hot rubber crack sealing and mastic crack sealing.

For homeowners, combining these repairs with regular driveway sealcoating helps protect your surface from both weather and traffic wear.

What Is Asphalt Crack Sealing

Crack sealing is the process of filling and sealing open cracks in asphalt pavement to prevent water and debris from entering. The goal is to keep moisture out of the base layer so it stays strong and stable.

It’s different from crack filling. Crack sealing uses flexible, rubberized materials that move with the pavement as temperatures change. Filling, on the other hand, is often a short-term fix with stiffer materials that don’t flex as well.

If the cracks are too wide or the surrounding asphalt is failing, it may be time to look at asphalt patching before sealing. Patching restores the surface so sealing can do its job properly.

How Hot Rubber Crack Sealing Works

Hot rubber crack sealing uses a rubberized asphalt compound heated to about 350 degrees and applied directly into cracks. Once it cools, it forms a flexible, waterproof seal that expands and contracts with Oklahoma’s temperature swings.

The process begins by cleaning the cracks with compressed air or heat to remove dust, weeds, and moisture. Sometimes the cracks are routed to create a uniform edge for better bonding. The hot rubber material is then applied using a specialized wand that fills the crack completely. Once the material cools, it forms a smooth seal that is ready for traffic in minutes.

This method works best for narrow cracks that are less than three-quarters of an inch wide. It’s a preventive maintenance technique designed to keep pavement in good shape. Hot rubber sealing typically costs less per linear foot than mastic applications, making it an economical choice for routine maintenance.

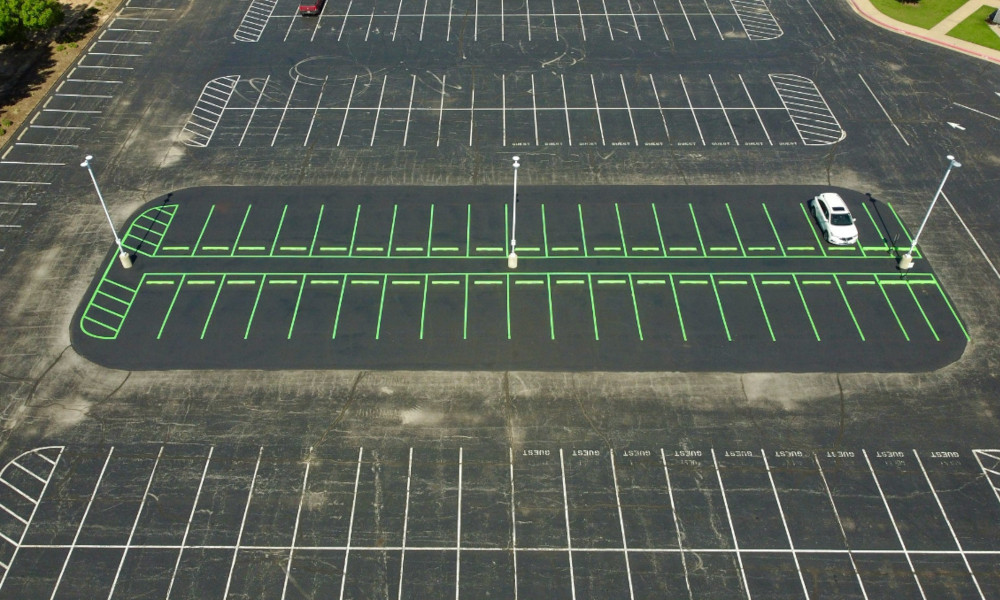

You’ll often see this used on parking lots, and residential driveways where the surface is still in fair condition.

Benefits of hot rubber crack sealing:

- Creates a waterproof barrier that keeps out moisture

- Helps prevent cracks from spreading

- Extends the life of the pavement by two to five years when maintained properly

- Fast installation and minimal downtime

- Cost-effective for smaller, preventive repairs

Many property owners choose to follow up with commercial sealcoating. Sealcoating adds a layer of protection across the entire surface and helps the crack sealant last even longer.

What Makes Mastic Crack Sealing Different

Mastic crack sealing uses a mix of rubberized asphalt and small aggregate stones. The added aggregate gives the material structure and prevents it from sinking into the crack over time. It’s thicker than hot rubber and designed for areas that need more than a simple seal.

The surface is cleaned just like with hot rubber sealing, but the material is applied wider to fill and cover larger damaged sections. Mastic is typically applied to cracks ranging from three-quarters of an inch to three inches wide, though it can handle even larger damaged areas. Once it cools, the result is a textured surface that blends smoothly with the surrounding pavement. The mastic material bonds tightly to the asphalt and resists cracking even under heavy loads.

Mastic is ideal for wide or irregular cracks, fatigue cracking, or worn joints. It’s often used on high-traffic areas like intersections, drive lanes, and commercial parking lots. While mastic costs more upfront than hot rubber sealing, its durability in demanding conditions often makes it the more economical choice over time.

Benefits of mastic crack sealing:

- Handles larger and more complex cracks

- Provides a strong, long-lasting repair with a five plus year lifespan

- Creates a smoother and safer surface for both vehicles and pedestrians

- Helps preserve surrounding pavement by keeping water out

- Better suited for high-traffic areas that experience heavy loads

When used as part of a broader maintenance plan that includes commercial paving, mastic sealing helps delay the need for costly resurfacing or reconstruction.

Hot Rubber vs. Mastic Crack Sealing: Choosing the Right Method

Understanding which crack sealing method to use can save you money and extend your pavement’s life. While both create waterproof barriers, they’re designed for different situations.

Choose hot rubber crack sealing when you have:

- Narrow cracks less than three-quarters of an inch wide

- Straight, linear cracking patterns

- Pavement in generally good condition with isolated cracks

- Residential driveways or low-to-moderate traffic areas

- A limited budget for preventive maintenance

- The need for quick repairs with minimal disruption

Choose mastic crack sealing when you have:

- Wide cracks from three-quarters of an inch to three inches or more

- Irregular crack patterns like alligator cracking

- Areas showing signs of surface deterioration

- High-traffic commercial lots, intersections, or drive lanes

- Shallow potholes or joint failures

- The need for a more durable, long-term repair

Key Differences at a Glance:

Hot rubber sealing is thinner, more flexible, and ideal for preventive maintenance on surfaces in good condition. It typically lasts two to five years and costs less per application. Mastic sealing is thicker, more structural, and designed for repairing moderate damage. It typically lasts five plus years and provides better performance under heavy traffic.

For property owners who aren’t sure which is right, a professional site inspection can help determine whether crack sealing, asphalt patching, or a combination approach is the best solution. In some cases, using hot rubber for minor cracks and mastic for problem areas creates the most cost-effective maintenance plan.

When to Schedule Crack Sealing in Oklahoma City

Crack sealing works best when the weather is dry and the pavement is warm but not hot. In Oklahoma City, spring and fall are often ideal times. The pavement temperature should be at least 40 degrees and rising for proper material adhesion.

Signs it’s time to seal include:

- Visible cracks or seams that collect dirt or water

- Small potholes forming along drive lanes

- Surface discoloration or edge crumbling

- Cracks that have grown noticeably over the past season

Because Oklahoma’s climate changes quickly, annual inspections help catch new cracks before they spread. Addressing them early is much less expensive than waiting until the surface needs major repair. A crack that costs a few dollars per linear foot to seal today could turn into a pothole requiring hundreds of dollars in patching tomorrow.

How Crack Sealing Fits Into a Maintenance Plan

Crack sealing is just one part of an effective pavement maintenance strategy. It pairs well with regular cleaning, patching, and sealcoating. Each step works together to prevent water from damaging the base and to keep the surface looking clean and smooth.

Businesses in Oklahoma City often include both crack sealing and commercial sealcoating in their yearly maintenance schedule. This combination creates a strong defense against sunlight, water, and traffic wear.

To learn more about the company’s full range of services, visit PavementPro Seal, where you can find details about asphalt repair, sealcoating, and paving for both residential and commercial properties.

The Value of Professional Crack Sealing

Proper crack sealing requires specialized equipment that most property owners don’t have access to. Professional contractors use high-temperature melters that heat materials to precise temperatures, routers that create clean crack edges for better bonding, and compressed air systems powerful enough to remove all debris and moisture from deep within the crack.

More importantly, experienced crews know how to read pavement conditions. They can identify when cracks are a surface issue or when they signal deeper base problems that need structural repair before sealing will be effective. This diagnostic ability prevents wasted money on repairs that won’t last.

Proper preparation is what separates successful crack sealing from failed attempts. A clean, dry crack allows the sealant to bond tightly and flex with the pavement as temperatures change. Without that preparation, even the best materials can fail within months. Professional crews also know how to avoid common mistakes like overfilling cracks, applying material in poor weather conditions, or using the wrong sealant type for the specific crack pattern.

Protecting Oklahoma City Pavement for the Long Term

Both hot rubber and mastic crack sealing play a major role in keeping asphalt strong and smooth. They help stop water from seeping into the base, reduce long-term damage, and stretch the life of your pavement investment.

Routine maintenance saves money and keeps your property looking professional and safe for visitors and customers. Studies show that every dollar spent on preventive maintenance like crack sealing saves four to ten dollars in future repair costs.

If your parking lot or driveway is showing early signs of cracking, schedule an inspection with a trusted local pavement maintenance company. Taking care of cracks today can prevent costly repairs tomorrow and help you get the maximum lifespan from your asphalt surfaces.